Optimization of OTIF (On Time and In Full) and Inventory Management in Your Company

Efficient inventory management and order fulfillment based on the OTIF (On-Time-In-Full) principle are essential for smooth collaboration with business partners.

Our solution provides complete control over inventory levels and delivery processes, resulting in improved product availability, cost optimization, and enhanced customer satisfaction.

OTIF – High-Standard in Order Fulfillment

What is OTIF, and Why is it Crucial?

OTIF measures whether orders are delivered on time and in full. Effective implementation of this metric helps avoid the following:

- Stock shortages and lost sales

Product shortages can lead to customer dissatisfaction and lost revenue. - Delivery delays

Timely deliveries are essential for maintaining operational continuity and customer satisfaction. - Uncontrolled operational costs

Inefficient supply chain management can drive up logistics costs.

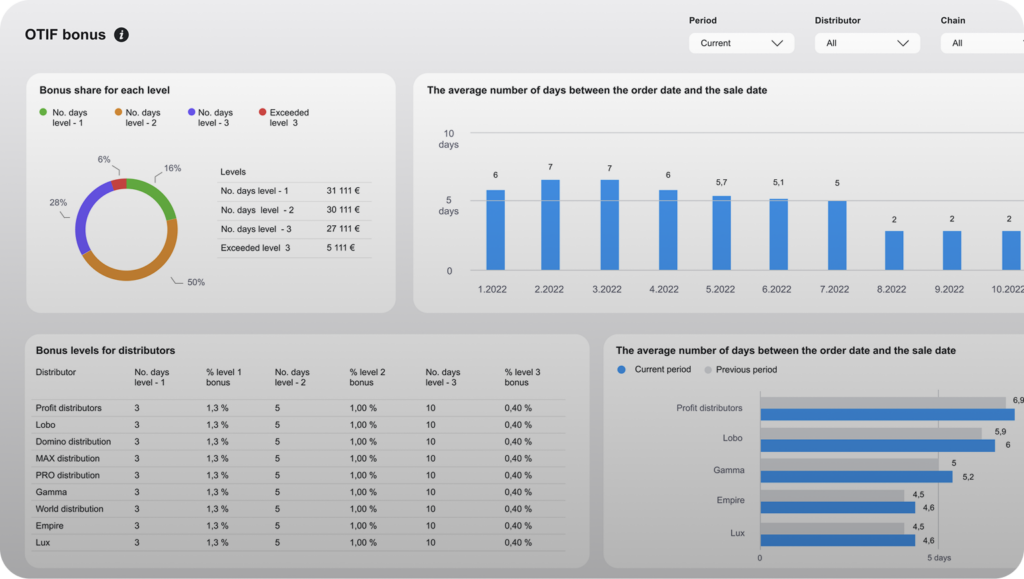

Our OTIF Solution Offers

- Real-time order fulfillment monitoring

Tracking order accuracy and timeliness. - Proactive supplier management

Identifying issues and implementing corrective actions. - Incentive system for distributors

Transparent bonuses for high-level order fulfillment.

Implementation Results

- Reduction of stock shortages

Maintaining optimal inventory levels minimizes the risk of out-of-stock products. - Faster order processing

Improving OTIF metrics leads to increased operational efficiency. - Sales growth

Better product availability directly contributes to higher revenue.

Smart Inventory Management

How to Effectively Manage Inventory and Avoid Losses?

A lack of adequate stock leads to lost sales, while excess inventory generates unnecessary costs. Our solution provides precise data and forecasts to help maintain optimal stock levels across the distribution network.

Key Features of the System

- Real-time inventory monitoring

Immediate response to stock level changes. - Dynamic inventory replenishment

(VMI – Vendor Managed Inventory) – Automating the ordering process to minimize excess or shortage risks. - Sales data analysis

Integrating data from distributors and retailers for better supply planning.

Business Benefits

- Reduction of frozen financial resources

Eliminating unnecessary stock enables more efficient capital utilization. - Faster inventory replenishment

Automated processes ensure inventory levels match current demand. - Complete supply chain visibility

Enabling better planning and logistics optimization.

Sources of Inventory Data

for Effective Management

To ensure real-time tracking and accurate forecasting of stock levels,

our system integrates data from multiple sources, including:

Individual Wholesale Warehouses

Monitoring stock availability at wholesale distribution centers to optimize replenishment strategies.

Individual Distributor Warehouses

Gaining insights into distributor-managed inventory levels to prevent overstocking or stockouts.

Logistics Centers

Tracking inbound and outbound product flows in large-scale logistics hubs.

Distribution Centers

Ensuring products are efficiently allocated to retail locations based on demand forecasts.

Central Warehouses of Retail Chains

Accessing aggregated stock levels at retail chain headquarters to support demand-driven replenishment.

Individual Retail Stores

Analyzing real-time stock availability at store level to enhance shelf availability and sales opportunities.

Cash & Carry Halls

Monitoring inventory in wholesale self-service markets to optimize bulk purchasing decisions.

Who Benefits from Implementing Our Solution?

Logistics Teams

Optimization of warehouse and transport processes leads to cost reduction and improved operational efficiency.

Finance Department

Improved control over operational budgets and logistics-related expenses.

Sales Teams

Better product availability and on-time deliveries increase customer satisfaction and sales results.

Trade Marketing

Department

Precise inventory and sales data enable better planning and execution of promotional activities.

Planning and Forecasting Department

More accurate demand forecasting and better production planning.

What sets us apart?

Data integration from multiple sources

Combining information from manufacturers, distributors, and retailers for a comprehensive market view.

Transparency and full control

Continuous tracking of OTIF and inventory metrics enables faster issue resolution.

Modular architecture

Our solution can be customized to fit the unique needs of any organization.

Get in touch

Uncover the full potential of the Asseco Platform.

"*" indicates required fields